PLATING

RACKS

COPPER CORE RACKS

Line Type: Automatic or Manual Lines

Used For: electrolytic processes

Contact: Copper or Stainless Steel

Coating on rack: Polypropylene or Halar

Our most widely sold racks are our Copper Core Racks.

M+B has always believed that a copper to copper connection was ideal for plating PCB's. Less resistance for the current, results in better plating throughout the board.

Whether coated with Polypropylene or Halar, our vertical copper core racks offer an optimal plating distribution by providing several contact points from the top of the panel to the bottom.

These are also ideal racks for plating flex or rigid-flex panels as they keep the board tightly fastened in place from both sides.

These racks can be made with or without a handle depending on if it is a manual or automatic plating line.

Advantages:

- Copper core provides excellent passage for current. Very little resistance

- Provide more contact points along the sides of the board, for a more even plating distribution

- Can be used in manual or automatic lines

- Can hold multiple panels on the same rack if needed

- Ideal for flex or rigid-flex panels

- In house repairs possible on our Polypropylene covered racks

T: 514-335-2436

F: 514-335-6008

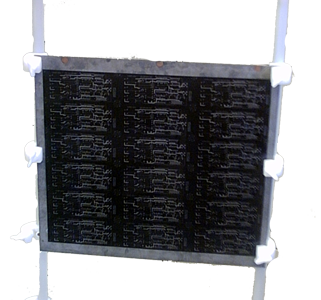

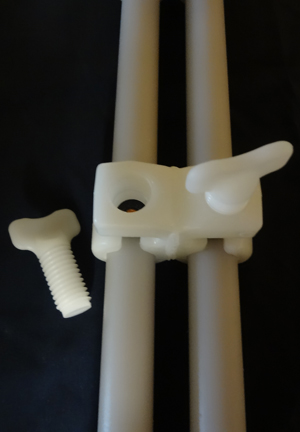

Flex rack: Open swivel block

Flex rack

Contact station

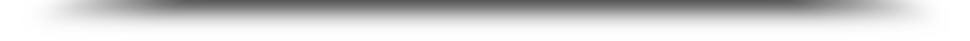

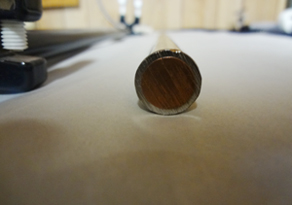

Clad copper rack, Halar coating

Clad copper next to finished rack

Contact station with thumbscrews

Clad Copper material